Introduction

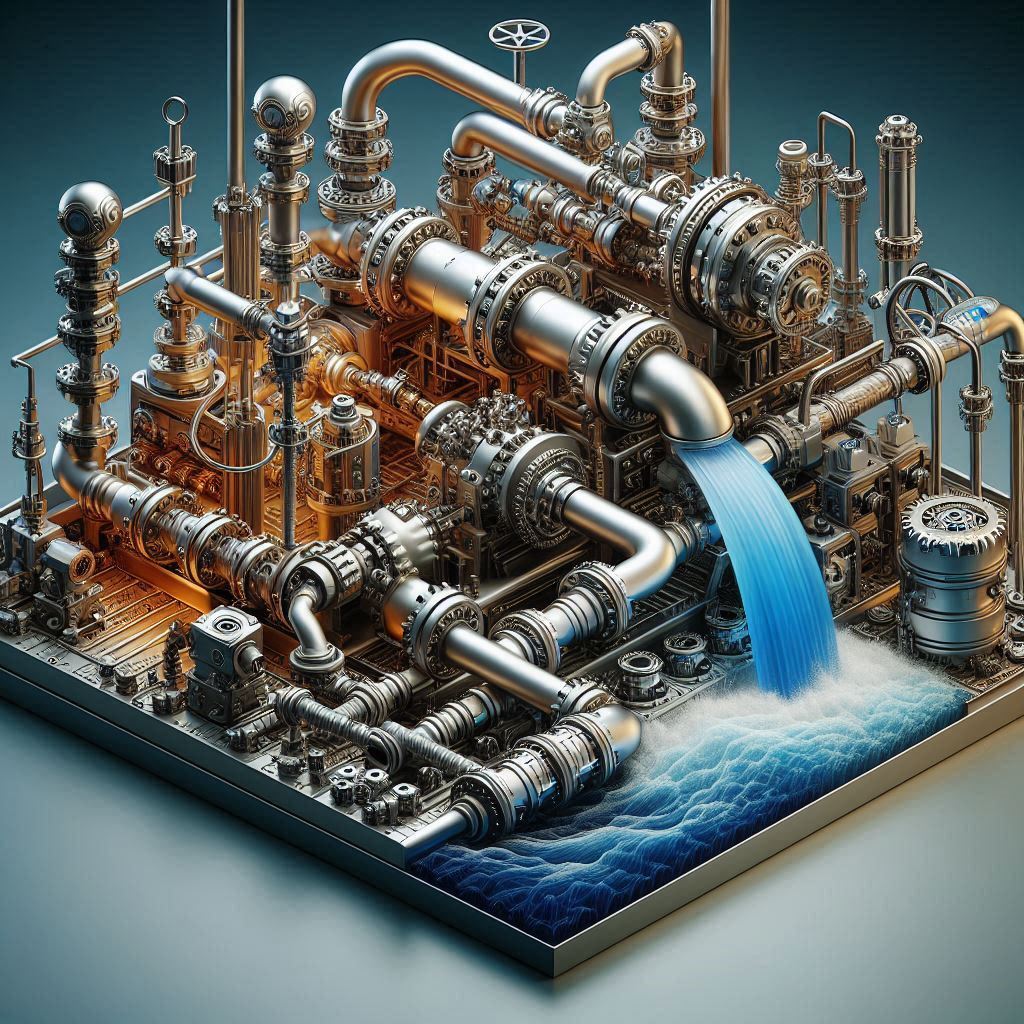

This guide explores enhancing the reliability of fluid flow systems, which are vital to industrial processes like chemical manufacturing and energy production. It addresses common issues, offers effective strategies, and aims to help engineers ensure smooth operations and minimize downtime.

Importance of Reliable Fluid Flow in Industrial Settings

The reliability of fluid flow systems can make or break industrial operations. When these systems function seamlessly, they ensure consistent product quality, reduce waste, and maintain optimal operational efficiency. Conversely, unreliable systems can lead to production halts, unsafe working conditions, and increased operational costs. Given their critical role, it’s clear that maintaining the reliability of fluid flow systems isn’t just a technical necessity—it’s a strategic imperative.

Operational Efficiency

First and foremost, reliable fluid flow systems help maintain high levels of operational efficiency. Consistent fluid flow means that processes can run without interruption, ensuring maximum productivity. When systems are reliable, there is less need for frequent troubleshooting, which saves time and resources.

Safety Concerns

Safety is another critical aspect influenced by the reliability of fluid flow systems. Leaks, bursts, or other system failures can pose serious risks to workers and the environment. Reliable systems minimize these risks by ensuring that fluids are transported safely and efficiently, reducing the likelihood of accidents.

Cost Implications

Finally, the financial implications of unreliable fluid flow systems cannot be ignored. Repairs and downtime can be expensive, and the indirect costs of lost productivity add up quickly. By enhancing reliability, companies can save significantly in both direct repair costs and indirect operational losses.

Common Challenges and Failures in Fluid Flow Systems

Despite their importance, fluid flow systems are prone to various challenges and failures. Understanding these common issues is the first step toward building more reliable systems.

Corrosion and Wear

One of the most pervasive problems is corrosion and wear. Over time, the materials that make up the system—pipes, valves, and seals—can degrade due to exposure to the fluids they transport. This degradation can lead to leaks, bursts, and overall system failure.

Blockages and Fouling

Blockages and fouling are other frequent issues. Particulates or sediment can accumulate within the system, impeding fluid flow and causing pressure build-ups. These blockages can be difficult to detect until they cause significant disruptions.

Mechanical Failures

Mechanical components such as pumps and compressors are also susceptible to failure. These components have moving parts that are subject to wear and tear. When they fail, the entire fluid flow system can come to a standstill.

Strategies to Enhance Reliability in Fluid Flow Systems

Improving the reliability of fluid flow systems involves a multi-faceted approach. Here are some key strategies that can make a significant difference.

Regular Maintenance Practices

Routine maintenance is vital for reliability. Regular inspections and servicing can catch issues early. Tasks include checking for corrosion, cleaning filters, and ensuring mechanical components work correctly.

Predictive Maintenance

Predictive maintenance uses data to forecast component failures, allowing timely interventions, reducing downtime, and extending lifespan.

Preventive Maintenance

Preventive maintenance includes routine tasks like lubricating moving parts, replacing worn components, and conducting system flushes to prevent blockages.

Upgrading System Components

Upgrading components, such as industrial piping like those in Utah, can enhance reliability. Older systems may use outdated materials prone to failure. Switching to more durable materials and advanced technologies can improve performance significantly.

Material Selection

Choosing the right materials is crucial. Resistant materials extend the system’s lifespan, reducing frequent repairs.

Technological Advancements

Using the latest technologies improves performance and reliability. Modern pumps, valves, and sensors outperform older models, offering long-term benefits.

Implementing Monitoring and Control Technologies

Monitoring and control technologies provide real-time insights into system performance, allowing quick issue resolution. These range from simple pressure gauges to advanced automated control systems.

Real-Time Monitoring

Real-time monitoring provides continuous data on system performance, helping identify trends and detect anomalies early for prompt action.

Automated Control Systems

Automated control systems adjust parameters in real-time to optimize performance and prevent failures, such as adjusting pump speeds or valve positions to maintain optimal flow and prevent pressure build-ups.

Future Trends in Fluid Flow System Reliability

Looking ahead, several emerging trends promise to further enhance the reliability of fluid flow systems.

AI and Machine Learning

Artificial intelligence and machine learning are set to revolutionize fluid flow systems. These technologies can analyze vast amounts of data to predict failures and optimize system performance.

Internet of Things (IoT)

The Internet of Things (IoT) will also play a significant role. Connected devices can provide real-time data and enable remote monitoring and control, further enhancing system reliability.

Sustainable Materials

The use of sustainable materials is another emerging trend. These materials offer improved durability and environmental benefits, making them an attractive option for future fluid flow systems.

Advanced Robotics

Advanced robotics can aid in the maintenance and repair of fluid flow systems. Robots can access hard-to-reach areas, perform inspections, and carry out repairs with precision and efficiency.

Conclusion

Enhancing the reliability of fluid flow systems is crucial for the success of industrial operations. By understanding common challenges and implementing effective strategies such as regular maintenance, upgrading system components, and leveraging monitoring technologies, you can significantly improve system performance.

Leave a Reply